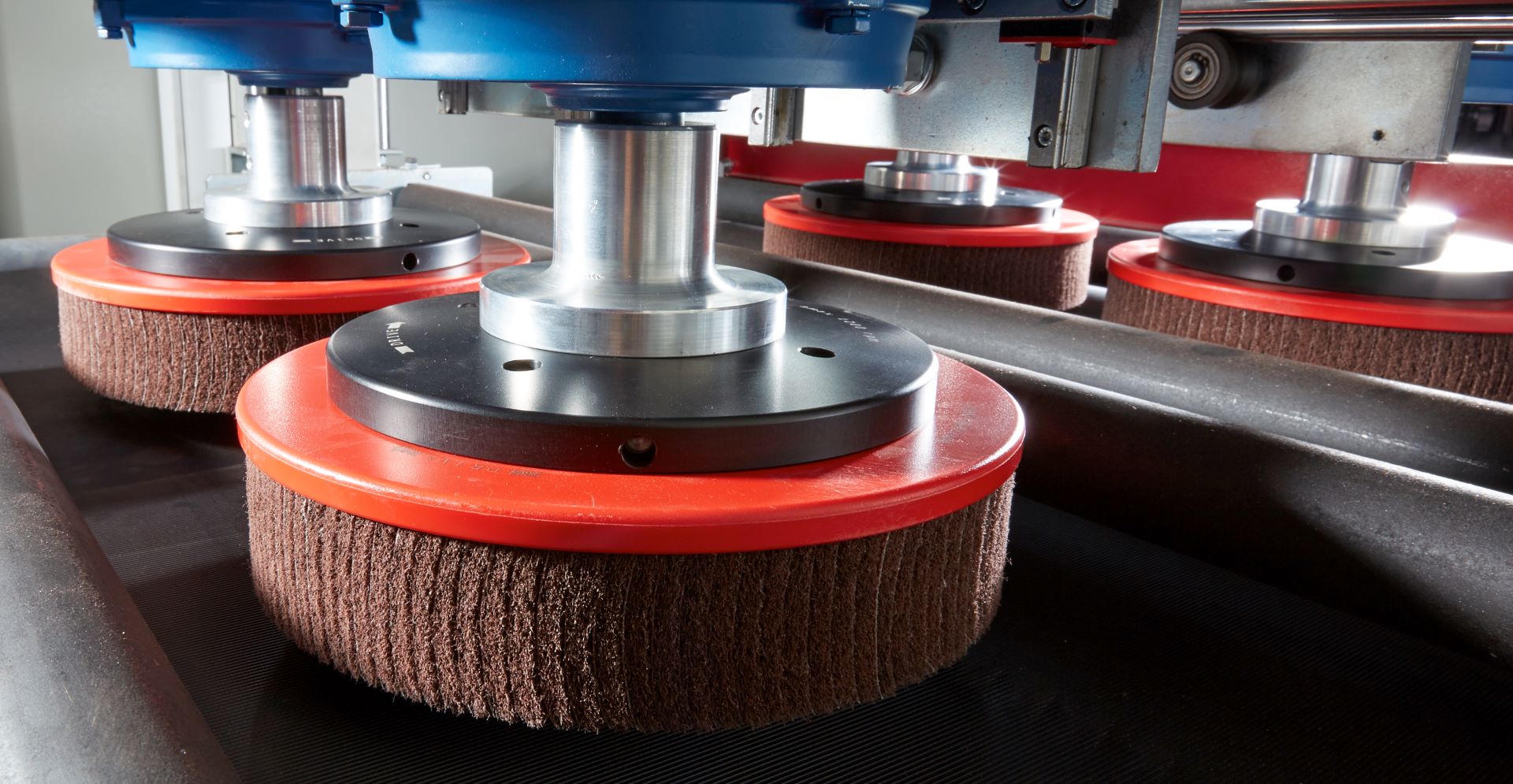

Setting the Benchmark for Industrial Surface Perfection

In the ever-evolving manufacturing landscape, precision and finish define product quality. At the forefront of this advancement is Valgro India, a name synonymous with high-performance surface preparation technologies. Known for engineering excellence, Valgro India has revolutionized the way industries approach metal finishing by delivering a cutting-edge deburring machine lineup. These machines have become an essential part of production lines where consistent edge refinement and flawless finishes are crucial.

Why Precision Matters in Metal Finishing

Precision metal finishing isn’t just about visual appeal. It plays a key role in product safety, functionality, and longevity. From aerospace to medical instruments, the slightest burr or edge imperfection can compromise performance or even lead to product failure. This is where the deburring machine from Valgro India becomes indispensable. Designed to handle intricate components and complex geometries, these machines ensure superior surface quality without compromising material integrity.

Valgro India’s Advanced Approach to Deburring

Valgro India’s innovation lies not only in technology but also in understanding industry-specific challenges. Their deburring machine systems are engineered with high adaptability, capable of finishing parts made of steel, aluminum, titanium, and other metals. These machines remove unwanted burrs formed during cutting, drilling, or milling, and simultaneously perform edge rounding for smoother finishes. The result is improved part performance, better coating adhesion, and enhanced product aesthetics.

Industry Applications That Trust Valgro’s Deburring Machine

A wide range of sectors benefit from Valgro India’s robust surface treatment solutions. Automotive manufacturers rely on these machines to prepare gears, engine parts, and braking systems. Electronics producers achieve safe and conductive contact points through burr-free surfaces. Medical device manufacturers trust the deburring machine to deliver the fine tolerances required for surgical tools and implants. Even the aerospace sector values the consistent and reliable performance of Valgro’s systems in critical component preparation.

Enhancing Production Efficiency Through Automation

One of the standout features of Valgro India’s offerings is the seamless integration of automation. Automated deburring machine systems reduce manual intervention, minimize error margins, and speed up processing time. This allows manufacturers to maintain uniform quality while optimizing production efficiency. Automation also enables precise repeatability, which is crucial for industries operating under strict quality control regulations.

Designed for High Output and Long-Term Reliability

Built with premium components, Valgro’s machines are known for durability, low maintenance, and energy efficiency. Whether it’s a standalone unit or a complete finishing cell, each deburring machine is rigorously tested to meet the most demanding industrial standards. The design ensures easy customization to cater to diverse part sizes, shapes, and material types, allowing clients to streamline their workflows and reduce operational downtime.

Tailored Solutions Backed by Technical Expertise

Valgro India stands apart by offering not just products but complete finishing solutions. Their team of engineers collaborates closely with clients to assess production requirements, material characteristics, and finish expectations. This consultative approach ensures every deburring machine configuration is optimized for maximum output and finish quality. Additionally, on-site training and technical support help clients derive full value from their investment.

Eco-Friendly Surface Finishing Technologies

As industries push toward sustainable manufacturing, Valgro India is committed to offering green solutions. Their deburring machine line incorporates dust extraction and low-energy systems to reduce environmental impact. By eliminating chemical finishing processes and minimizing waste, these machines not only protect the environment but also help companies meet regulatory compliance more efficiently.

Valgro India: Driving the Future of Surface Engineering

The journey of innovation never stops at Valgro India. With continuous research, customer feedback, and technological upgrades, the company remains a driving force in industrial surface finishing. The deburring machine continues to evolve with smarter controls, IoT integration, and greater energy efficiency to meet tomorrow’s production challenges.

Conclusion – Redefining Metal Finishing with Precision and Power

Precision, performance, and productivity – these are the pillars on which Valgro India has built its legacy. Their advanced deburring machine solutions are not just machines, but strategic tools empowering industries to achieve higher standards of quality and consistency. From small-scale workshops to large-scale manufacturing facilities, Valgro’s commitment to excellence ensures that every component, every surface, and every edge meets perfection.